Applications

Marking & Coding

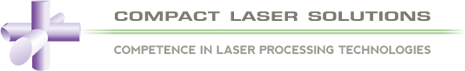

Inscription, Engraving, Individual, Marking, Part Traceability

Laser marking can be implemented by inducing very different material reactions, for example by

- heating, e.g. for black annealing markings on steel

- material removal, e.g. for engravings on silicon or ceramics

Machining

Cutting, Drilling, Structuring, Layer Removal, Microablation

Laser machining is especially adequate for rapid prototyping of complex structures.

MachiningIndustrial Implementation

Facility Integration, System Networking, Data Transfer, 24/7 Production

Whether OEM laser source or laser marking system, our laser products are ready to be integrated in an increasingly digital fabrication environment.

More information about this applicationScientific Application

Research & Development, Spectroscopy, Sensor and Monitoring

Laser technology plays a very important role in science, whereas the large variety of attainable parameters sets ground for groundbreaking results.

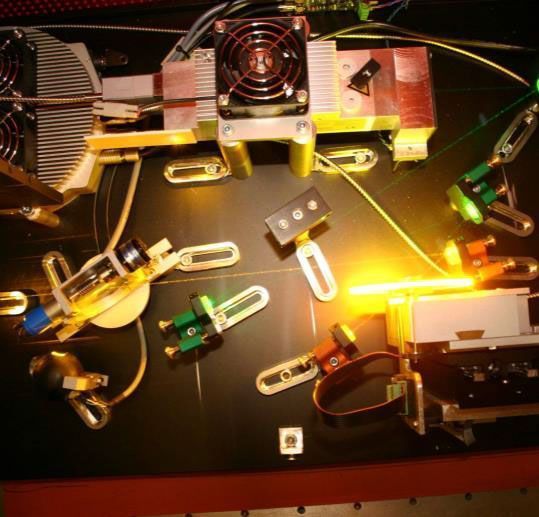

More information about this applicationThe right choice of laser wavelength

1064 nm (IR), 532 nm (Green) OR 355 nm (UV)

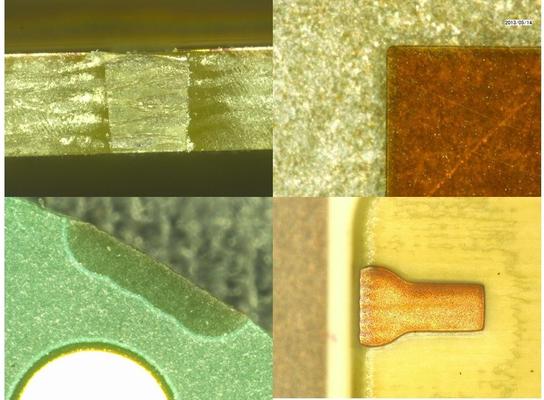

The operation of the air-cooled, diode-pumped Q-switched laser sources of Compact Laser Solutions generating short laser pulses of <10ns is the right choice for any application, at which high quality should be achieved under stringent economic frame conditions. At Compact Laser Solutions, laser sources at three different wavelengths are available: 1064 nm, 532 nm or 355 nm. Which wavelength is the right choice for you depends on the to be processed material of the work piece and your application goals.

More information about this application