The right choice of the laser wavelength

1064 nm (IR) OR 532 nm (Green) OR 355 nm (UV)

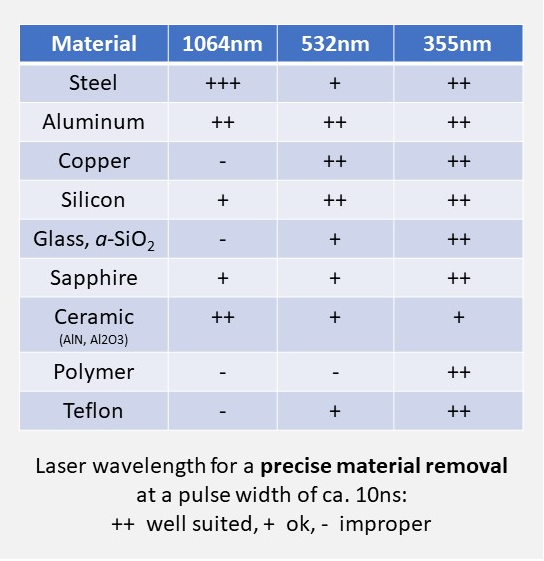

The operation of the air-cooled, diode-pumped Q-switched laser sources of Compact Laser Solutions generating short laser pulses of <10ns is the right choice for any application, at which high quality should be achieved under stringent economic frame conditions. At Compact Laser Solutions, laser sources at three different wavelengths are available: 1064 nm, 532 nm or 355 nm. Which wavelength is the right choice for you depends on the to be processed material of the work piece and your application goals.

A reduced optical penetration depth is an important precondition for precise material removal with a suppressed heat affected zone (HAZ) outside of the to be processed volume. For a precise machining of some metals, such as copper or gold, the reduction of laser wavelength from 1064 to 532 nm is of great advantage, since the optical penetration depth and, hence, the HAZ is strongly decreased. Focused pulsed laser light at 532 nm is even capable of effectively machining in manageable quality transparent materials, such as glass, fused silica or diamond.

Utilization of short-pulsed UV laser light

For almost all materials the optical penetration depth is lower for 355 nm (UV) compared to 532 nm. Diode-pumped UV solid-state laser sources with a pulse width at <= 10 ns offer the best conditions for a high-quality machining at moderate cost-of-ownership:

- Most materials, e.g. metals, semiconductors, glass, sapphire and polymers, absorb pulsed UV laser light at 355 nm very effectively.

- The minimal optical penetration depth at 355 nm reduces significantly the HAZ.

- Laser light at 355 nm offers the advantage of a smaller focus spot, which is important for the fabrication of small structures and inscriptions.

- The combination of short wavelength, smaller focus spot size and short pulse width is a great prerequisite to utilize non-linear optical effects, as in the machining of normally highly transparent materials.

Micro Ablation and Heat Affected Zone

Certainly, there also exist applications where a large optical penetration depth is of advantage. A good example is the carbonization of polymers, that can be used for dark marking of the plastic surface. In this case, a laser source generating pulsed radiation at 532 nm or 1064 nm may be utilized to induce the reaction (heat) deeper into the material. On the other hand, the same polymer can be cut free from any signs of carbonization using pulsed UV laser light for a minimal optical penetration depth, allowing for a precise micro ablation with every single laser shot.

Hence, the right choice of laser wavelength always depends on the application and the required results. Our team will gladly advise you on this query.